West Pharma

Problem TBC. Solution TBC. Burner Summary Rating: TBC Fuel: TBC Manufacturer: TBC Working Pressure: TBC Operation: TBC Year: TBC

NUTRICIA (DANONE)

Problem The client required a new boiler to meet their operational requirements. Solution We decided to install a Cochran Thermax which met the client’s specification. This proved to be the most cost effective option. Burner Summary Name: Cochran Thermax Output: 15,880 KG/HR Working pressure: 17 Bar G Fuel: Dual fuel Saacke burner

FOYLE PROTEINS

Problem To repair and replace the steam boilers refractory due to general usage erosion. Works carried out Brickwork and Refractory Repairs on Thermal Oxidiser and waste heat steam boiler. Service Ongoing regular repairs during annual shutdown.

HUHTAMAKI

Problem To reduce future cost by installation of a smaller more efficient boiler saving 6% of annual fuel costs. Solution A complete new installation of a Cochran Thermax package steam boiler with economism and a service contract to maintain the boiler and equipment including the existing Thermax boiler for a period of 5 years. Solution A complete new installation of a Cochran Thermax package steam boiler with economism and a service contract to maintain the boiler and equipment including the existing Thermax boiler for a period of 5 years. Service contract (5 year) To provide services of an experienced boiler operator to attend to the boiler and equipment in the boiler house to PM5 recommendation. To include refractory replacement and ultrasonic testing when required and also be responsible for all…

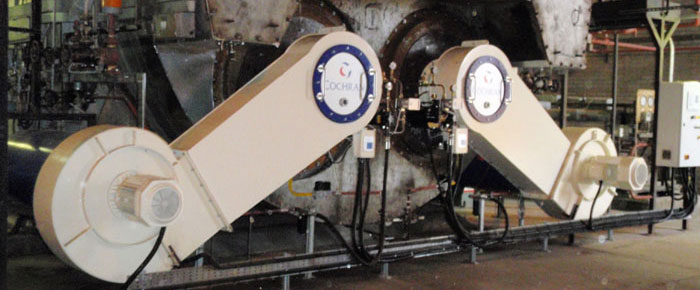

KILROOT POWER STATION

Problem The existing boilers were over 30 years old, inefficient and getting spare parts was an on-going problem.Solution Two Cochran Equinox Pressure Jet Burners were installed which inorporate the autoflame Mk6 Micro Modulation combustion control logic. This method of control ensures that optimum combustion efficiency is achieved throughout the burner firing range and the direct drive servo motor control prevents hysteresis, which is inherent in merchanical linkage type burner plant. The Micro Modulation combustion logic also provides the capability to interface with variable speed drive control, flue gas trim and displays the boiler operating parameters in real-time.Burner Summary Rating: 29830 KG/HR Fuel: Light Oil Manufacturer: Cochran Type: Equinox Operation: Modulating Turn Down Ratio: 3.74:1

MAUDS ICE CREAM

Problem Mauds Ice Cream plant in Carrickfergus required steam supply for new process. Solution Geoff Castles Boilers provided a turnkey supply and installation to satisfy their requirements. Servicing As well as the install we were able to supply training for Maud’s staff and total service and breakdown backup for their ongoing needs. Mauds boiler was a Control Flame rated at 450Kg/Hr.

KNOCKBRACKEN HEALTH CARE

[metaslider id=362] ProblemThe boilers needed to be installed over 200 metres of grass without the ground being disturbed. Knockbracken health care had two steam boilers which were proving to be inefficient and costly to repair. Solution A crane and truck with a lift was hired along with treaded matts to place along the grass in order to transport the boiler without damaging the premises. The two inefficient boilers were replaced with a more efficient Cochran boiler which can burn both Oil and Gas. Burner Summary Output: 2000 KG/HR Fuel: Natural Gas and Oil Working Pressure: 10 Bar G Type: Simplex Pressure Jet Combustion Control: High / Low Turn Down Ratio: 2:1

BALLYRASHANE CREAMERY

Problem The Creamery wanted to change to Natural Gas because it became available. This allowed the client to greatly reduce their fuel bills. Solution The main goal of this installation was to reduce the overall cost of fuel. This was done by installing Dual Fuel Burners oil and Gas with Electronic controls and variable speed fans. The boilers come fitted with flue gas economisers and Auto blowdown and Tds blowdown which should increase the boilers efficiency by 5 – 7%. Burner Summary Output: 2 x 5000 KG/HR Fuel: Natural Gas and Oil Working Pressure: 10 Bar G